© Mohammad Hassan Ettefagh | Tabiat Bridge in Tehran designed by Architect Leila Araghian.

General Information

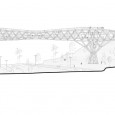

Name: Tabiat Pedestrian Bridge (Tabiat means Nature in Farsi Language)

Location: Modarres Highway, Abbas Abad Lands,Tehran, Iran

Architect firm: Diba Tensile Architecture

Architect: Leila Araghian

Design Team: Alireza Behzadi, Sahar Yasaei

Detail Design: Homa Soleimani, Mina Nikoukalam

Project Collaborators: Atieh Ghafouri, Hoda Kameli, Msaoud Momeni, Elaheh Khajouyee, Farhad Elahi

Date of design: September 2009 – December 2010

Date of Construction: October 2010- October 2014

Site Area: 6 ha

Ground Floor Area: 3200 sqm

Built Area: 7680 sqm

Length: 270 meter

Building Type: Structure, Public Buildings

Structure Engineering Co: Maffeis Engineering

Mechanical Engineer: Aram Shahriari

Electrical Engineer: Mahmoud Abolhasani

Supervisors: Alireza Behzadi, Adel Mohammadi, Payam Golfeshan

Head of Supervisors: Nader Naghi pour

Contractor: Shahid Rajaee Co.

Construction Company: Azar Teif Sepahan Co.

Executive Team: Alireza Jafarian-Akbar pourgholi-Amir Naeemi-Meisam Ale Ali- Arash Kamali

Executive Manager (Civil): Hossein Saemi

Executive Manager (Structure): Mojtaba Keshtkar

Photos: Mohammad Hassan Ettefagh, Sina Ahmadi

Competition: Pedestrian Bridge Design over Modarres Highway, organized by Nosazi Abasabad, 2008

Awards:

- Awarded project to be constructed in a competition for the pedestrian bridge over Modarres Highway in 2009

- The Best Steel Structure in Bridge Section on the 4th Conference of Steel and Structure 2013, Tehran, Iran

- The Golden Brick of Tehran in Development of Leisure & Touristic Spaces on the World Cities day presented by UN-Habitat and Tehran Municipality, 2014, Tehran, Iran